Your Trusted Welded Branches Supplier in Malaysia

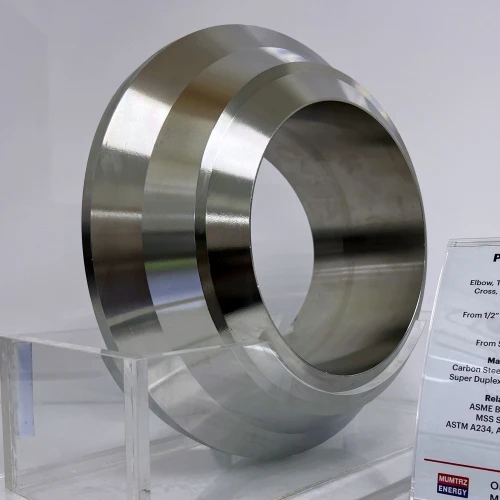

With over a decade of expertise, Mumtaz Energy stands as a leading supplier of premium welded branches. Our dedication to excellence has earned the trust of clients across the region. As a premier supplier in Malaysia, we provide a comprehensive range of welded branches, including Olets, Weldolets, Threadolets, Sockolets, Nipolets, Weldoflanges, and Nipoflanges, designed for critical applications in oil and gas facilities.

At Mumtaz Energy, we take pride in offering welded branches that adhere to the highest industry standards and are meticulously tailored to meet the specific demands of your oil and gas operations.

Our welded branches comply with international standards, including:

- MSS SP-97, Covers integrally reinforced branch outlet fittings for piping systems

- ASME B31.1, Pressure Piping

- ASME B31.3, Governs the design of process piping, including branch connections

- ASME B16.25, Buttwelding Ends

- MSS SP-25, Standard Marking

- ASME B16.9, Specifies dimensions and tolerances for factory-made wrought steel butt-welding fittings

- ASME Section III

Overview of Welded Branches in Piping Systems

Welded branches, also known as outlets, are essential components in piping systems, enabling the connection of secondary pipes to a main pipeline. They ensure fluid flow from the main pipe to a branch pipe without compromising the system’s integrity. This overview delves into the types, functions, standards, and manufacturing processes associated with welded branches.

What are Welded Branches (Weldolet, Threadolet, Sockolet, Nipolet, Weldoflange, & Nipoflange)?

Welded branches, or outlet fittings, are specialized components designed to create strong and reliable connections between a primary pipe and a branch pipe. These fittings come in various forms, each tailored to specific applications within a piping system:

- Weldolet: A butt-weld fitting used for high-pressure systems, providing a smooth transition between the main pipe and branch.

- Threadolet: A threaded outlet fitting, commonly used for small bore branching. Sockolet: A socket weld outlet ideal for high-pressure applications where space is limited.

- Nipolet: A combination of an outlet and a nipple, used in low-pressure systems.

- Weldoflange: A flange type outlet designed for flanged connections, integrating the branch and flange into a single piece.

- Nipoflange: Similar to a weldoflange, but with an extended neck, combining a nipple and a flange.

Application of Welded Branches

Welded branches serve critical roles in piping systems by facilitating the connection of branch lines to a main pipeline. Their functions include:

- Flow Diversion: Directing the flow of fluids from the main pipeline to the branch pipe.

- Pressure Handling: Maintaining system pressure integrity at the branch connection point.

- Structural Support: Providing mechanical support and stability at the branching junction.

- Leak Prevention: Ensuring a leak-proof connection through precise welding techniques.

Manufacturing Process of Welded Branches

The manufacturing of welded branches involves several critical steps to ensure they meet the required specifications and standards:

- Material Selection: High-quality steel or alloy is chosen based on the application and environmental conditions.

- Cutting and Shaping: Raw material is cut and shaped into the desired form, whether it’s a Weldolet, Sockolet, or another type.

- Forging: The shaped material undergoes forging to enhance its strength and durability.

- Machining: Precision machining is performed to achieve the exact dimensions and tolerances specified in the standards.

- Heat Treatment: The component is heat-treated to relieve stresses and improve mechanical properties.

- Inspection and Testing: Non-destructive testing (NDT) is conducted to ensure the branch meets quality standards and is free from defects.

- Surface Finishing: Finally, the branch fitting is polished and coated, if necessary, to protect against corrosion.

As a trusted supplier of Weldolet, Threadolet, Nipolet, Sockolet, Weldoflange, and Nipoflange in Malaysia, Mumtaz Energy delivers high-quality products that meet international standards, ensuring safety and optimal performance for your projects. Contact us today to discover the perfect solution for your piping needs.

Welded Branches Specification

| Specification | Options |

|---|---|

| Type | Weldolet Elbowlet Threadolet Sockolet Weldoflange Nipoflange |

| Size | Run pipe: From 3/4″ to 48″ Branch size (small size): From 1/2″ to 24″ |

| Schedule/ Rating | Common: Sch40, Sch80, SchXS, Sch160, SchXXS Uncommon: Between Sch5 to Sch130, Specific WT in mm Olet Rating: 3000#, 6000#, or 9000# Flange Rating: 150#, 300#, 600#, 900#, 1500#, or 2500# |

| Face for flange | Flat face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Material Grade Standard

| Material | Standard/Grade/Symbol |

|---|---|

| Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service | ASTM A234/A234M Gr WPB ASTM A234/A234M Gr WPC ASTM A234/A234M Gr WP5 ASTM A234/A234M Gr WP9 ASTM A234/A234M Gr WP11 ASTM A234/A234M Gr WP12 ASTM A234/A234M Gr WP22 |

| Wrought Austenitic Stainless Steel Piping Fittings | ASTM A403/A403M WP304/WP304L ASTM A403/A403M WP316/WP316L ASTM A403/A403M WP317/WP317L |

| Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service | ASTM A420/A420M WPL6 ASTM A420/A420M WPL9 ASTM A420/A420M WPL3 ASTM A420/A420M WPL8 |

| Wrought Ferritic, Ferritic/Austenitic, and Martensitic Stainless Steel Piping Fittings | ASTM A815/A815M S31803 ASTM A815/A815M S32205 ASTM A815/A815M S32750 ASTM A815/A815M S32760 ASTM A815/A815M S32550 |

| Carbon Steel Forgings for Piping Applications | ASTM A105/A105M |

| Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components | ASTM A350/A350M Gr LF1 ASTM A350/A350M Gr LF2 ASTM A350/A350M Gr LF3 ASTM A350/A350M Gr LF5 ASTM A350/A350M Gr LF6 ASTM A350/A350M Gr LF9 |

| Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service | ASTM A182/A182M Gr F304 ASTM A182/A182M Gr F304L ASTM A182/A182M Gr F316 ASTM A182/A182M Gr F316L ASTM A182/A182M Gr F316Ti ASTM A182/A182M Gr F310 ASTM A182/A182M Gr F310H ASTM A182/A182M Gr F317 ASTM A182/A182M Gr F317L ASTM A182/A182M Gr F50 ASTM A182/A182M Gr F51 ASTM A182/A182M Gr F53 ASTM A182/A182M Gr F55 ASTM A182/A182M Gr F60 ASTM A182/A182M Gr F65 |

Ordering Information

- Nipoflange, 4″ X 3/4″, 600#, SCH80 X SCH80, ASTM A105N, MSS SP-97, ASME B16.50

- Weldoflange, 4″ X 3/4″, 600#, SCH80 X SCH80, ASTM A105N, MSS SP-97, ASME B16.50

- Weldolet, 2″ X 1″, SCH160, ASTM A182 F51, MSS SP-97

- Threadolet, 2″ X 1″, 3000#, ASTM A105N, MSS SP-97

- Sockolet, 2″ X 3/4″, 6000#, ASTM A105N, MSS SP-97