Your Trusted Temporary Strainers Supplier in Malaysia

With over a decade of expertise, Mumtaz Energy stands as a leading supplier of premium Temporary Strainers. Our unwavering commitment to excellence has earned the trust of clients throughout the region. As a premier supplier in Malaysia, we provide a comprehensive selection of temporary strainers, including basket strainers, conical (cone) strainers, and plate (flat) strainers, all engineered for critical applications in oil and gas facilities.

At Mumtaz Energy, we take pride in delivering Temporary Strainers that adhere to the highest industry standards, meticulously crafted to meet the unique demands of your oil and gas operations.

Our fabricated temporary strainers meet all relevant piping dimension standards, including:

- ASME B16.5

- ASME B16.47 Series A

- ASME B16.47 Series B

- Welding Procedure Specification (WPS)

Overview of Temporary Strainers in Piping System

What are Temporary Strainers?

Temporary strainers, also known as basket strainers, conical (cone) strainers, and plate (flat) strainers, are critical components used in various piping systems to ensure the smooth operation of fluid transport and processing systems. Each type serves a specific purpose:

- Basket Strainers: These are cylindrical filters that capture debris in a basket-like mesh structure. They are typically used in pipelines with larger flow volumes.

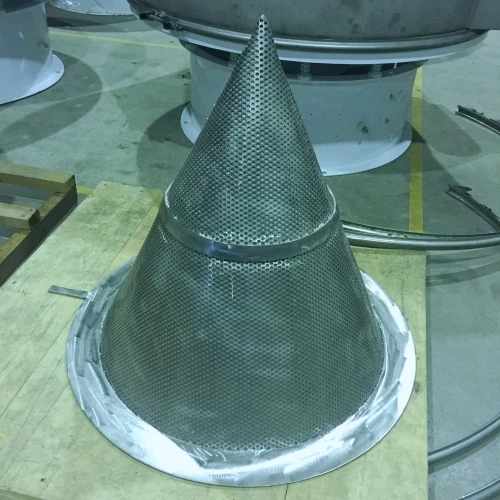

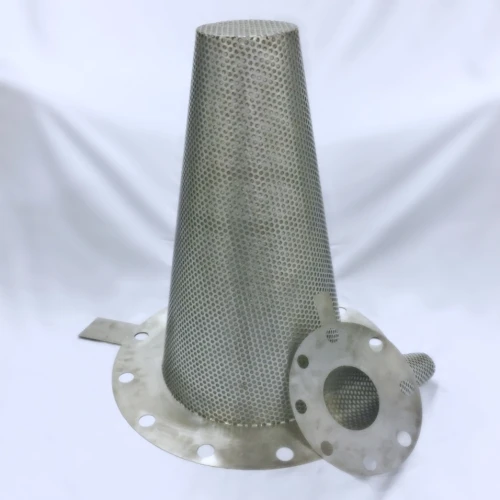

- Conical/Cone Strainers: Featuring a conical shape, these strainers are designed to handle higher flow rates and are often used in applications where space is limited.

- Plate/Flat Strainers: These strainers use a flat screen to filter out particles and are ideal for installations where a compact and low-profile design is required.

Application of Temporary Strainers

Temporary strainers play a vital role in protecting downstream equipment from damage caused by debris and contaminants. They are commonly used during:

- Pipeline Construction and Maintenance: To remove particulates during the initial stages of system setup and maintenance.

- Equipment Start-Up: To prevent damage to new or repaired machinery by filtering out debris during initial operations.

- System Flushes: To catch particulate matter during cleaning or flushing processes.

List of Standards Regarding Temporary Strainers

Temporary strainers are designed and fabricated in compliance with several industry standards to ensure performance and reliability:

- ASME (American Society of Mechanical Engineers): Specifies the design, materials, and testing requirements for strainers used in pressure piping systems.

- MSS (Manufacturers Standardization Society): Provides guidelines on the specifications and performance of strainers in various applications.

Fabrication of Temporary Strainers

The fabrication of temporary strainers involves several key steps:

- Material Selection: Typically made from stainless steel or other corrosion-resistant alloys to ensure durability and longevity.

- Design: Strainers are designed according to application requirements, including mesh size and strainer type.

- Manufacturing Process: Includes welding, machining, and assembly to produce strainers that meet stringent quality standards.

Advantages of Temporary Strainers

Temporary strainers offer several benefits, including:

- Protects Equipment: Prevents damage to downstream machinery and instrumentation by removing debris from the fluid stream.

- Cost-Effective: Provides a low-cost solution for protecting critical equipment during initial system operations.

- Ease of Maintenance: Designed for easy installation and removal, allowing for quick cleaning or replacement as needed.

- Versatility: Available in various types and sizes to suit different applications and flow rates.

For more information or to discuss your temporary strainer needs, please contact us. Our team of experts is here to help you find the perfect solution for your piping system.

As a trusted supplier of Basket Strainers, Conical (Cone) Strainers, and Plate (Flat) Strainers in Malaysia, Mumtaz Energy provides high-quality products that meet international standards. Our strainers are designed to ensure safety and optimal performance for your projects. Contact us today to find the perfect solution for your piping needs.

Temporary Strainers Specification

| Specification/Part | Options |

|---|---|

| Body – Perforated Plate | Plate Thickness: 1 to 3 mm Open Area: 3.6 to 64.5% Hole Diameter: 2.4 to 6mm Pitch: 4.8 to 9.3mm |

| Mesh | Plain Weave or Intermediate Crimp Mesh 1 to Mesh 150 |

| Handle | Plate Thickness: 1 to 5mm |

| Ring/Flange Plate | Plate Thickness: 1 to 5mm |

| Stiffener Ring/Plate | Plate Thickness: 1 to 5mm |

| End Cap (optional) | 1/2″ to 2″ Pipe size |

* Any custom design requires detailed drawings.

* Detailed drawings or sketches may be required before fabrication begins.

Material Grade Standard

| Material | Standard/Grade/Symbol |

|---|---|

| Austenitic Stainless Steels Stainless Steel | SS 304/304L SS 316/316L |

| Ferritic-Austenitic Stainless Steels Duplex Stainless Steel & Super Duplex Stainless Steel | UNS S31803 UNS S32750 UNS S32760 UNS S32205 |

Ordering Information

Detailed drawings required