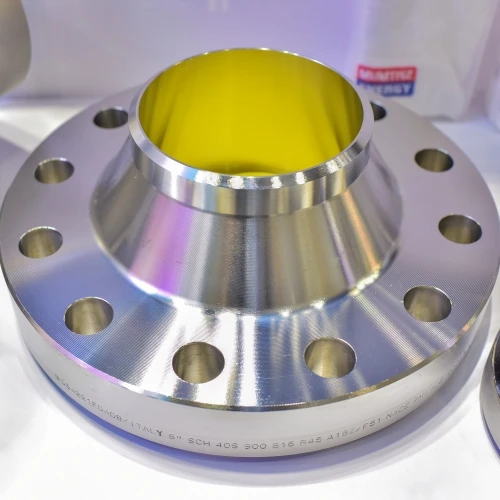

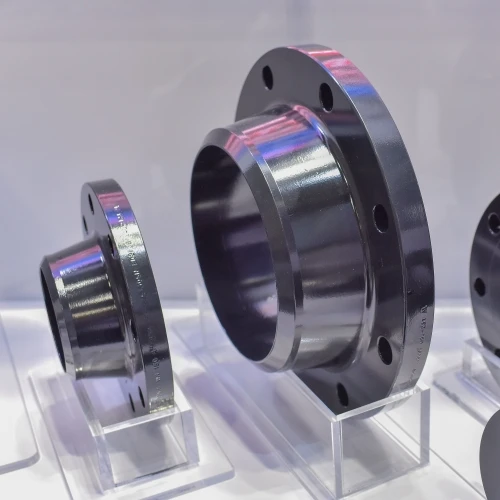

Your Trusted Flanges Supplier in Malaysia

With over a decade of expertise, Mumtaz Energy stands out as a leading supplier of high-quality forged flanges. Our commitment to excellence has earned us the trust of clients across the region. As a top flange supplier in Malaysia, we offer an extensive range of flanges, including Weld Neck, Blind, Slip-on, Threaded, Socket Weld, Lap Joint, Long Weld Neck, and Orifice Flanges.

At Mumtaz Energy, we take pride in delivering only the highest quality forged flanges, carefully tailored to meet the specific needs of our valued customers.

Our flanges comply with international standards, including:

Understanding the ASME/ANSI B16.5 Flanges

The ASME/ANSI B16.5 standard governs the design and manufacture of flanges and flanged fittings made from cast or forged materials. It also includes blind flanges and certain reducing flanges made from cast, forged, or plate materials. This standard specifies essential requirements for flange bolting, gaskets, and joints, ensuring a reliable and secure connection.

Additionally, ASME/ANSI B16.5 covers the size, class rating, face types, and wall thickness (schedule) of flanges, ensuring they meet the stringent demands of various applications.

Understanding the ASME/ANSI B16.47 Flanges

The ASME B16.47 standard is essential for larger pipe flanges, covering sizes from 26″ to 60″ with pressure class ratings of 75, 150, 300, 400, 600, and 900. This standard is divided into two categories: Series A and Series B, specifically for blind and weld neck flanges.

Differences Between ASME B16.47 Series A and Series B:

- Series A: These flanges are thicker, heavier, and stronger than Series B, making them ideal for applications requiring higher external load capacity. However, they are generally more costly.

- Series B: These flanges require more but smaller fasteners and have a smaller bolt circle diameter, resulting in reduced flange movement after installation. They are commonly chosen for refurbishment or replacement projects.

Both Series A and B include weld neck and blind flanges with raised face types. Additionally, Series A features ring-type joint (RTJ) flanges from Class 300 to Class 900, which are not included in Series B.

Understanding the ASME/ANSI B16.36 Flanges (Orifice Flange)

Orifice flanges are essential for measuring the flow rate of liquids or gases in pipelines. These flanges feature pairs of pressure taps, usually positioned on opposite sides, to facilitate accurate measurement. Additional instrumentation can be customized based on your specific application needs.

Orifice flanges are similar in structure to standard B16.5 weld neck, slip-on, and threaded flanges but include extra machining to accommodate the pressure taps. They typically come with Raised Faces or Ring Type Joint (RTJ) facings.

A set of two orifice flanges is often referred to as an Orifice Set Union or Orifice Pair, with an Orifice Plate mounted between the flanges. This setup is used to measure flow, and the type of Orifice Plate varies depending on the project’s requirements. A jack screw is also installed to help separate the flanges during inspection or replacement of the Orifice Plate and gaskets.

Understanding the API 6A Flanges: API 6B & API 6BX Flanges

The API 6A standard, developed by the American Petroleum Institute, shares many similarities with ANSI/ASME flanges. Although dimensionally similar, API 6A flanges are designed for higher pressure requirements, starting at 2000#. While 6BX flanges can handle pressures up to 25,000#, the more common API 6B flanges typically range from 2000# to 5000#.

All API flanges feature Ring Type Joint (RTJ) facings and require proper gaskets to ensure optimal performance. These higher pressure specifications cater to the demanding environments of petrochemical and oilfield applications, including wellheads and drilling equipment. API flanges are also used in downstream refinery and processing applications to convert crude oil into consumer products.

API 6B Flanges:

API 6B flanges are designed with Ring Type Joint facings and are not intended for face-to-face make-up. The connection relies on the metallic ring gasket, with sizes ranging from 2-1/16″ to 21-1/4″ and pressure ratings of 2000#, 3000#, and 5000#.

API 6BX Flanges:

API 6BX flanges also use Ring Type Joint facings but feature a raised face. The connection’s bolting force can act on the raised face when the gasket is properly seated, providing additional support and preventing damage from excessive bolt torque. Sizes range from 2-1/16″ to 21-1/4″ with pressure ratings of 10,000#, 15,000#, and 20,000#.

Understanding EN 1092-1 Flanges

The European standard EN 1092-1 specifies the requirements for steel flanges used in piping systems, including details on nominal pressure (PN) and dimensions (DN). This standard also outlines various flange types, their sealing surfaces, tolerances, threading, and labeling.

Each flange in our inventory adheres to EN 1092-1 standards and is meticulously labeled to provide clear information on its construction and intended application. This comprehensive classification system ensures that you receive flanges that meet precise technical specifications and performance criteria.

Understanding BS 10 Flanges

BS 10 flanges conform to the British Standards BS 4504 and BS 10:1962, which specify the dimensions and material requirements for flanges used in piping systems. The BS 4504 standard covers flanges and bolting for pipes, valves, and fittings, with dimensions available in pressure ratings such as PN6, PN10, PN25, and PN40.

Pressure Ratings BS 10 Flanges

BS 10 Flanges: Rated for PN2.5, PN6, PN10, PN16, PN25, and PN40.

BS 10 flanges and ASME flanges are available in similar types, including Slip-On, Weld Neck, Plate, Blind, Socket Weld, Threaded, and Lap Joint.

As a top flange supplier in Malaysia, Mumtaz Energy offers high-quality flanges that meet international standards, ensuring safety and performance for your projects. Reach out to us today to find the perfect flange solution for your needs.

Flange Specifications

| Specification | Options |

|---|---|

| Type | Weld Neck Flanges Slip On Flanges Blind Flanges Lap Joint Flanges Threaded Flanges Socket Weld Flanges Orifice Flanges Plate Flanges |

| Size | 1/2″ (DN15) to 48″ (DN1200) |

| Class/Rating | ASME/ANSI: 150#, 300#, 600#, 900#, 1500#, or 2500# JIS: 5K, 10K, 16K, 20K, 30K BS EN1092-1: PN6, PN10, PN16, PN25, PN40, PN63, or PN100 API 6A: 2000#, 3000#, 5000#, 10000#, 15000#, or 20000# |

| Face Type | Raised Face (RF) Flat/Full Face (FF) Ring Type Joint (RTJ) |

| Schedule | Common: Sch40, Sch80, SchXS, Sch160, SchXXS Uncommon: Between Sch5 to Sch130, Specific WT in mm |

| Standard | ASME B16.5 ASME B16.47 Series A ASME B16.47 Series B JIS B 2200 BS EN 1092-1 |

As a leading flange supplier in Malaysia, Mumtaz Energy offers high-quality flanges in various types, sizes, and specifications that adhere to international standards. Ensure safety and performance for your projects—contact us today to find the perfect flange solution.

Material Grade Standard

| Material | Standard/Grade/Symbol |

|---|---|

| Carbon Steel For high-temperature and high-pressure environments | ASTM A105 ASTM A105N |

| Carbon Steel Alloy Low Alloy-Steel For low-temperature service with notch toughness testing | ASTM A350 Gr LF1 ASTM A350 Gr LF2 ASTM A350 Gr LF3 ASTM A350 Gr LF5 ASTM A350 Gr LF6 ASTM A350 Gr LF9 |

| Carbon Steel and Alloy-Steel For high pressure (high yield) liquid transmission | ASTM A694 Gr F42 ASTM A694 Gr F46 ASTM A694 Gr F50 ASTM A694 Gr F52 ASTM A694 Gr F56 ASTM A694 Gr F60 ASTM A694 Gr F65 ASTM A694 Gr F70 |

| Austenitic Stainless Steels Stainless Steel | ASTM A182 Gr F304 ASTM A182 Gr F304L ASTM A182 Gr F316 ASTM A182 Gr F316L ASTM A182 Gr F316Ti ASTM A182 Gr F310 ASTM A182 Gr F310H ASTM A182 Gr F317 ASTM A182 Gr F317L |

| Ferritic-Austenitic Stainless Steels Duplex Stainless Steel & Super Duplex Stainless Steel | ASTM A182 Gr F50 ASTM A182 Gr F51 ASTM A182 Gr F53 ASTM A182 Gr F55 ASTM A182 Gr F60 ASTM A182 Gr F65 |

As a leading flange supplier in Malaysia, Mumtaz Energy provides high-quality flanges in a range of materials that meet international standards. Ensure safety and optimal performance for your projects—contact us today to find your ideal flange solution

Ordering Information

Sample of flange full description :

Weld Neck Flange, 10″, 300#, Sch40, RF, ASME B16.5, ASTM A182 F55